Factory Tour

Raw Materials

Pipes and Tubes are manufactured using raw materials from authorized sources. Technical criteria established by the quality assurance department and pertinent technical specifications determine the quality requirements for raw materials.

Welded Pipes and Tubes

According to the needs of the customer, American Stainless Industries has a facility for TIG welded tube with bead rolling.

As a result of the critical and corrosive environments that stainless steel tubes are used in, the quality of the tubes is maintained with a precise tolerance in accordance with the necessary national and international standards.

Large Diameter Pipes

The Large Diameter Pipes are subsequently sized and straightened using a hydraulic press with a 150 M.T. capacity to match the specifications' dimensional criteria. Tests are carried out under specifications and further quality checks using the hydrostatic or X-ray technique.

On a 1000 M.T. hydraulic press, welded stainless steel pipes with lengths of up to 6.0 to 7.0 meters are manufactured. SS pipes are produced in this section using TIG welding and filler materials under ASTM A 358.

Cold Drawing Section

The American Stainless has installed draw benches for Cold Drawing of Tubes & Pipes for Seamless and Welded products.

When drawing on top-quality Tubes, a thin layer is created on both the exterior and interior of the Tubes by coating each one individually with chemicals and soap. The tubes are then pulled to decrease their diameter and thickness using a tungsten carbide die and plugs. They are solution annealed once more. Before packaging and dispatch, the item was straightened, pickled, hydro-tested, passivated, labeled correctly, and subjected to the suggested tests.

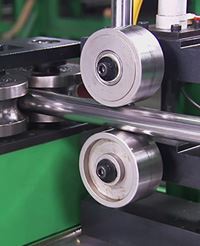

Cold Pilger Section

The longitudinal cold-rolling method known as cold pilgering decreases the diameter and wall thickness of metal tubes in a single operation. Depending on the material, the cold Pilger method can reduce the cross-section by more than 90% in a single working cycle.

The cold pilgering process relies on four main actions: The tube moves forward and it rotates while the ring dies move back and forth and rotate.

Annealing

A fully automated roller hearth furnace with temperature recorders and controls is used for annealing or heat treating the Tubes. It entails quickly quenching the Tubes after heating them to a specific temperature.

- Reduce hardness and increase plasticity,

- Refine grain and eliminate tissue defects

- Eliminate internal stress

- Prepare for quenching the organization

Manufacturing Facilities in House

- Tube Mill Machines

- Draw Bench Machines

- Pillager Machines

- Steel Rolling Mill Machinery

- Stainless Steel Pipe-Tube Polishing Machine

- Cold Forming Machine (1500 MT)

- Straightening Machines

- H-Frame 200 Ton Presses

- Hydraulic Press (300 MT)

- 600 MT Hydraulic Press (SR Hydraulics)